When embarking on an electronics project that incorporates sound alerts or notifications, selecting the appropriate Buzzer PCB Mount becomes crucial. The Buzzer PCB Mount serves as the vital link between the circuitry and the functional component of the buzzer, ensuring secure placement and optimal performance within your device. With a myriad of options available in the market, it can be challenging to navigate which mount best suits your specific project requirements.

In this comprehensive guide, we will explore the various factors to consider when choosing a Buzzer PCB Mount. From compatibility with different buzzer sizes and shapes to the mounting options available, understanding these elements will be pivotal in making an informed decision. The guide aims to equip you with the knowledge necessary to select a mount that enhances your project’s functionality and reliability, allowing your electronic design to thrive. Whether you are a seasoned engineer or a hobbyist, mastering the art of selecting the perfect Buzzer PCB Mount will significantly contribute to the success of your project.

When working on electronic projects, understanding the basics of buzzer PCB mounts is crucial for ensuring optimal performance and integration. Buzzer PCB mounts serve as the physical interface between the buzzer component and the printed circuit board, providing a stable and reliable connection. They come in various shapes and sizes, catering to different design requirements. When selecting a buzzer mount, it is essential to consider factors such as thickness, mounting style, and additional features like vibration resistance or environmental protection, which can significantly influence the functionality and longevity of the buzzer.

Another essential aspect to consider is the electrical characteristics of the buzzer mount. Depending on the type of buzzer—passive or active—the specifications for voltage and current ratings will differ. It is also important to evaluate the sound output requirements, including volume and frequency range, to ensure that the mount allows for optimal sound transmission. Properly aligning the buzzer with the PCB mount not only enhances acoustic performance but also helps mitigate issues such as interference or sound distortion. Overall, by grasping these fundamental aspects of buzzer PCB mounts, you can make informed decisions that elevate the quality and effectiveness of your electronic projects.

When selecting a buzzer PCB mount for your project, it’s essential to understand the different types available in the market. Primarily, you'll encounter three categories: piezoelectric buzzers, electromagnetic buzzers, and electromechanical buzzers. Each type serves a distinct purpose and is suited for specific applications. For instance, piezoelectric buzzers are favored for their high efficiency and compact size, making them ideal for portable devices. In contrast, electromagnetic buzzers produce a stronger sound output, often utilized in alarm systems and industrial applications where loud audible alerts are necessary.

Another crucial aspect is the mounting style, which can significantly impact the performance and installation of the buzzer. Surface mount and through-hole mount are the two predominant styles available. Surface mount buzzers offer a smaller footprint and are quicker to assemble, while through-hole buzzers provide more robust connections, which can be beneficial in applications with higher mechanical stress. According to industry reports, the demand for surface mount technology is projected to grow by 20% over the next five years, highlighting a shift towards compact design solutions in electronics.

Tips: When choosing, consider the acoustic performance and frequency range of the buzzer, as it directly affects the clarity and volume of the sound produced. Additionally, check the environmental ratings to ensure that the buzzer can withstand the operating conditions of your project. Don't overlook the importance of testing different types to see which meets your project's requirements best, as this can lead to optimal performance and reliability.

When choosing a buzzer PCB mount for your project, several factors should be considered to ensure optimal performance and compatibility. First, you need to assess the size and form factor of the buzzer itself. The dimensions should match the design of your PCB layout while providing ample space for installation. Additionally, consider the mounting style—whether through-hole or surface-mount—as this will dictate the assembly process and ultimately influence reliability in various applications.

Another critical factor is the sound output specifications, which include volume level and frequency range. Depending on the project requirements, you might need a buzzer that operates at higher frequencies or produces a louder sound. Understanding the environmental conditions, such as temperature and humidity, will also help in selecting a buzzer mount that can withstand these factors without compromising performance.

Tips: Always look for a buzzer with a suitable operating voltage that matches your circuit specifications. Additionally, consider the power consumption of the buzzer to ensure it aligns with your energy budget, particularly for battery-operated devices. Lastly, reviewing the manufacturer's datasheet can provide insights into the recommended PCB layout for optimal acoustic performance.

When it comes to installing buzzer PCB mounts in your project, attention to detail can significantly impact performance and reliability. Proper installation techniques not only ensure that the buzzer functions effectively but also prolongs its lifespan. According to a recent industry report by Research and Markets, the global PCB mount segment is expected to grow by 6.7% annually, highlighting the increasing importance of proper installation practices.

To begin with, it’s essential to choose the correct size and type of PCB mount that fits your circuit design. Ensuring that the mount suits both the physical dimensions of the PCB and the electrical specifications of the buzzer is critical. The mounting hole should be cleanly drilled and free from debris to prevent any potential short-circuits or mechanical failures. Moreover, using the right soldering technique is vital; a clean solder joint not only enhances conductivity but also prevents cold joints that could lead to intermittent failures.

Finally, securing the buzzer during installation is a key step in enhancing durability. Reports indicate that vibration and thermal cycling can lead to loosening over time, hence employing appropriate adhesives or retaining clips can mitigate this risk. Ensuring that the buzzer is mounted securely also protects against environmental factors, such as moisture and dust, which can adversely affect performance. In an industry where reliability is crucial, meticulous installation of buzzer PCB mounts can significantly contribute to the success of your project.

| Buzzer Type | Mounting Style | Operating Voltage | Sound Level (dB) | Size (mm) | Notes |

|---|---|---|---|---|---|

| Piezo Buzzer | Surface Mount | 3-12V | 85 | 20x20 | Commonly used in alarms |

| Magnetic Buzzer | Through Hole | 5-24V | 90 | 30x30 | Loud sound with lower power |

| Active Buzzer | Surface Mount | 3-12V | 75 | 15x15 | Requires DC voltage to operate |

| Passive Buzzer | Through Hole | 3-12V | 70 | 12x12 | Requires AC signal to produce sound |

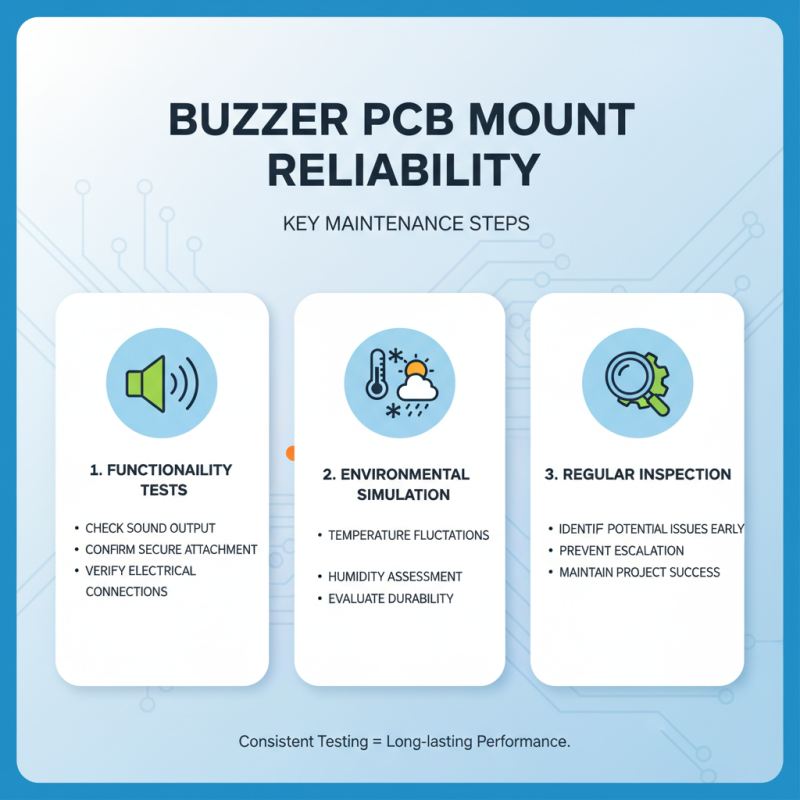

When working with buzzer PCB mounts, ensuring their reliability and performance is crucial for the success of your project. Regular testing is a key component of maintaining these mounts, which can help identify any potential issues before they escalate. Begin by conducting functionality tests, where you check the sound output of the buzzer under different conditions. This will help confirm that the mount is securely attached and that the electrical connections are functioning as intended. It’s also beneficial to simulate various environmental factors, such as temperature fluctuations or humidity, to assess the durability of the mount over time.

In addition to testing, proper maintenance practices can prolong the life of buzzer PCB mounts. Keeping the PCB clean is essential; dust and debris can create electrical interference or physical obstruction. Utilize appropriate cleaning tools, such as soft brushes or lint-free wipes, to gently remove any contaminants without damaging the components. Furthermore, regularly inspect the mounts for signs of wear, such as cracks or corrosion, which could indicate that it’s time for replacement. Creating a maintenance schedule can ensure these checks are performed consistently, ultimately enhancing the overall reliability of your buzzer mounts in a project setting.