In the realm of industrial weighing and force measurement, the significance of Piezoelectric Load Cells has gained increased recognition due to their precision and reliability. According to a report by Markets and Markets, the global load cell market is projected to reach USD 3.9 billion by 2025, driven largely by the growing demand in industries such as pharmaceuticals, aerospace, and manufacturing. The versatile applications of Piezoelectric Load Cells, coupled with their ability to provide real-time data and withstand harsh environments, make them indispensable tools in modern engineering practices.

Dr. Lisa Thompson, a leading expert in sensor technology, emphasizes the value of these devices: "Piezoelectric Load Cells not only offer superior accuracy but also enhance operational efficiency by ensuring precise load measurements." This growing body of evidence highlights how the integration of Piezoelectric Load Cells into various systems has transformed the landscape of load measurement, leading to advancements in automation and improved quality control.

As industries continue to evolve and emphasize automation, the demand for high-performance load cells is set to rise further. Understanding how Piezoelectric Load Cells function across different applications will provide invaluable insights into their operational advantages and contribute to the ongoing innovations in measurement technology.

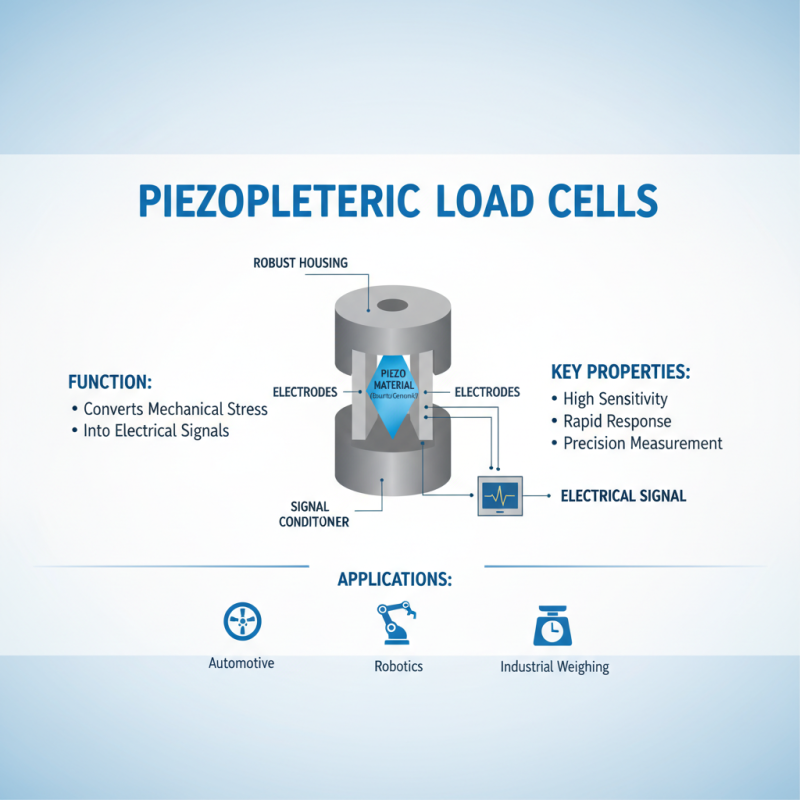

Piezoelectricity is a phenomenon where certain materials generate an electrical charge in response to applied mechanical stress. This property is critical to the operation of piezoelectric load cells, which convert weight and force into an electrical signal that can be measured accurately. When a load is applied to a piezoelectric sensor, the mechanical deformation of the material leads to the generation of an electric charge proportional to the load. This is particularly useful in applications ranging from industrial weighing systems to precision scales used in research laboratories.

One notable advantage of piezoelectric load cells is their sensitivity and fast response time, enabling them to capture dynamic changes in force accurately. These load cells are often utilized in situations where quick and precise measurements are essential, such as in robotics, medical devices, and aerospace engineering. The sensors also tend to have excellent linearity and stability, making them ideal for long-term use in various settings.

**Tips:** When selecting a piezoelectric load cell, consider the specific requirements of your application, such as the range of forces to be measured and the environmental conditions. Additionally, ensure that the load cell is compatible with your data acquisition system to optimize performance. Regular calibration and maintenance can help sustain accuracy and reliability over time.

Piezoelectric load cells are sophisticated devices designed to convert mechanical stress into electrical signals. The construction of these load cells typically involves a piezoelectric material enclosed within a robust housing. Common piezoelectric materials include quartz crystals and certain ceramics, which exhibit the piezoelectric effect—generating an electrical charge in response to applied pressure. This unique property allows for high sensitivity and rapid response times, making them ideal for precision measurement in various applications.

The design of piezoelectric load cells also emphasizes minimal hysteresis and excellent linearity, allowing for accurate readings over a wide range of loads. Their compact structure often incorporates multi-axis sensing capabilities, which is beneficial in applications where forces may be applied in different directions. Furthermore, the housing is engineered to withstand harsh environmental conditions, ensuring durability and reliability. In addition to traditional industrial uses, these load cells are increasingly utilized in applications ranging from aerospace testing to medical devices, where precision and responsiveness are critical.

Piezoelectric load cells are innovative devices that utilize the piezoelectric effect to measure force or weight in various applications. The working mechanism is based on the principle that certain materials generate an electric charge in response to mechanical stress. When a load is applied to a piezoelectric material, it deforms, generating a charge proportional to the applied force. This charge is then converted into an electrical signal, which can be measured and interpreted by electronic systems. According to a market research report published by Technavio, the demand for piezoelectric sensors, including load cells, is expected to grow at a compound annual growth rate (CAGR) of approximately 7% from 2021 to 2025, driven by their enhanced accuracy and reliability.

In industrial applications, piezoelectric load cells play a critical role due to their ability to deliver precise measurements even in dynamic environments. They excel in high-speed applications such as robotics and automation, where rapid changes in load need to be monitored accurately. A study by the International Society of Automation noted that systems employing piezoelectric load cells have shown an increase in measurement accuracy of up to 25% compared to traditional load cells. Their compact design also allows for integration in tight spaces, making them ideal for various fields, including aerospace, automotive testing, and materials testing. The versatility and reliability of piezoelectric load cells position them as essential tools in modern measurement technology.

This chart illustrates the output response of piezoelectric load cells under different load conditions. The data represents how the voltage output varies with increasing load, showcasing the sensitivity and precision of piezoelectric load cells in various applications.

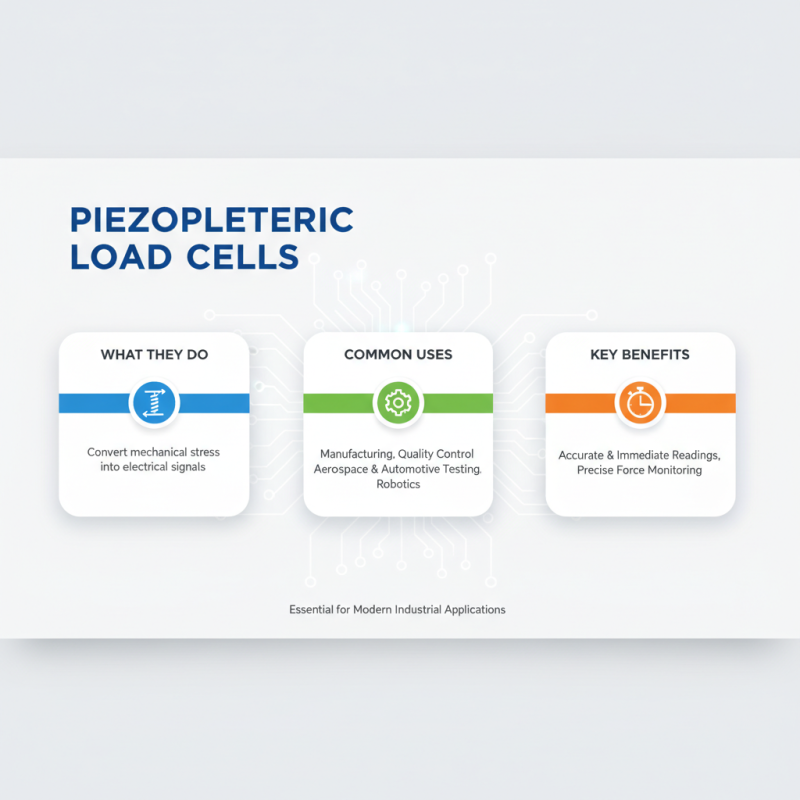

Piezoelectric load cells are vital components in various industrial applications due to their ability to convert mechanical stress into electrical signals. These sensors are commonly utilized in manufacturing processes, quality control, and dynamic force measurement in aerospace and automotive testing. Their ability to provide accurate and immediate readings makes them indispensable in situations requiring precise force monitoring, such as weigh stations, material testing, and even robotics.

When implementing piezoelectric load cells, it's crucial to consider their sensitivity and response time. In applications where quick variations in force are expected, such as in dynamic weighing systems, selecting a load cell with a fast response time ensures accurate measurements without lag. Additionally, maintaining the load cell's calibration is essential for consistent performance.

Tip: Ensure that the load cell is installed in a vibration-free environment to prevent erratic readings. Regular calibration checks can enhance the longevity and accuracy of the piezoelectric load cell, making it a reliable choice across various industrial settings. From monitoring the weight of products on a conveyor belt to assessing the structural integrity of bridges, piezoelectric load cells play an integral role in maintaining efficiency and safety in industrial operations.

Piezoelectric load cells are widely used in various applications due to their unique ability to convert mechanical stress into electrical signals. One of the primary advantages of these load cells is their high sensitivity and rapid response time. This makes them ideal for dynamic measurements where changes in load need to be detected quickly, such as in weighing systems and force measurement applications. Additionally, piezoelectric load cells can operate in extreme conditions, including high temperatures and aggressive environments, which broadens their applicability in industrial settings.

However, piezoelectric load cells also have certain limitations that need consideration. They generally exhibit drift over time, especially under static loading conditions, which can affect measurement accuracy. Furthermore, these load cells require a certain level of dynamic loading to produce reliable readings, making them less suitable for static applications where constant loads are applied. Their complexity in terms of required electronics for signal conditioning can also be a drawback, as it adds to overall system costs and may require specialized knowledge for maintenance and calibration. Understanding these advantages and limitations is crucial for selecting the appropriate load cell for specific applications.