In the world of technology, an Ultrasonic Emitter plays a vital role. Dr. Emily Carter, an expert in acoustic engineering, once stated, "Ultrasonic Emitters create waves that are invisible yet impactful." These devices convert electrical energy into high-frequency sound waves. They are used in numerous applications, from cleaning delicate items to pest control.

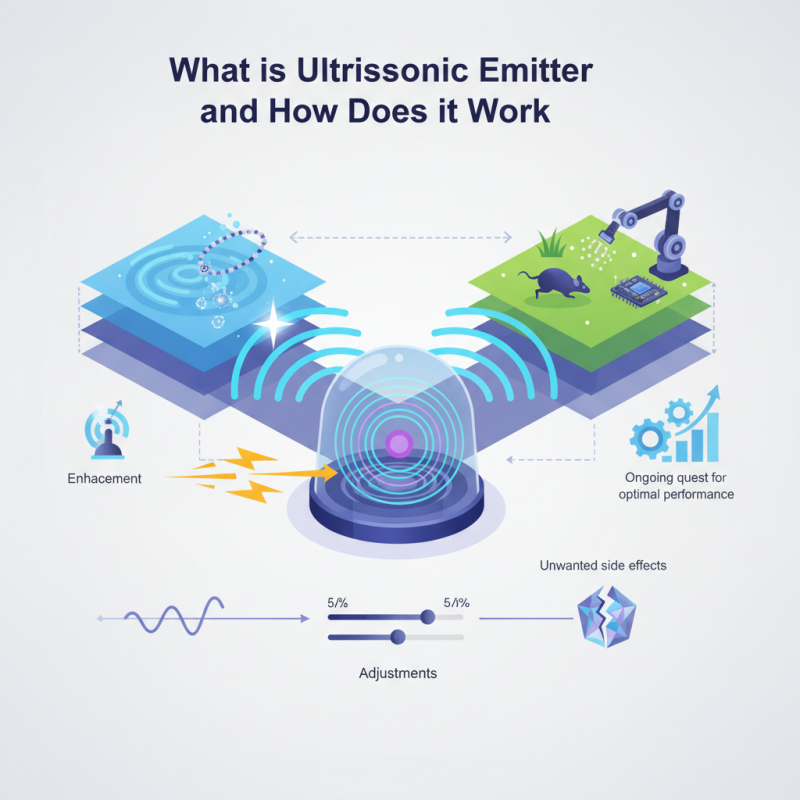

Understanding how an Ultrasonic Emitter works requires delving into the science behind ultrasonic waves. These waves travel through different mediums, interacting with objects along their path. The technology, although efficient, can sometimes produce unwanted side effects. For instance, not all materials respond well to ultrasonic treatment. Some may require adjustments in frequency and intensity.

Moreover, the precision of Ultrasonic Emitters can vary based on the technology used. As noted, the quest for optimal performance is ongoing. While the applications are promising, there is always room for improvement. The industry continues to evolve, focusing on minimizing errors and enhancing efficiency. This complexity makes the topic both fascinating and challenging.

An ultrasonic emitter is a device that produces ultrasonic waves. These waves are sound waves with frequencies above the audible range for humans, typically above 20 kHz. Ultrasonic emitters find use across various fields, including medical imaging and cleaning applications. They can generate precise waves that reflect off surfaces, making them valuable in non-invasive diagnostics.

In the medical field, ultrasonic emitters are integral to ultrasound imaging. They create real-time images of soft tissues in the body. This technology allows for early detection of conditions without invasive procedures. Additionally, ultrasonic cleaners use emitters to agitate a cleaning solvent, removing dirt or grime from intricate items. The high-frequency sound waves produce tiny bubbles that gently wash away contaminants.

While ultrasonic emitters are effective, challenges exist. The quality of the emitted sound can vary based on design and environment. Some emitters may not achieve the desired range or frequency. Careful calibration is essential for optimal performance. There's also the potential for unintended interference in sensitive applications. Hence, it’s crucial to address these aspects to enhance their effectiveness.

| Feature | Description | Applications |

|---|---|---|

| Frequency Range | Typically between 20 kHz and 1 MHz | Industrial cleaning |

| Working Principle | Converts electrical energy into ultrasonic sound waves | Medical imaging and therapy |

| Materials | Commonly made from piezoelectric materials | Non-destructive testing |

| Power Consumption | Varies based on design, typically low | Pest control |

| Durability | High resistance to environmental conditions | Ultrasonic welding |

Ultrasonic emitters operate on the principle of converting electrical energy into high-frequency sound waves. These sound waves typically exceed 20 kHz, above the range of human hearing. The process begins with the piezoelectric effect, where certain materials deform under an electric field, generating sound waves. This mechanism is crucial in various applications, such as cleaning, sensing, and pest control.

Research indicates that ultrasonic cleaning can reduce the cleaning time by up to 90%. This efficiency arises from the high-frequency vibrations that agitate cleaning solutions. The emitted ultrasonic waves create microscopic bubbles in the liquid. These bubbles collapse rapidly, a phenomenon known as cavitation. This collapse produces high local temperatures and pressure, effectively dislodging contaminants.

Understanding the limitations of ultrasonic technology is essential. While it is effective for certain applications, it may not work well with all materials. Some objects can be damaged if exposed to high frequencies. Moreover, the distance from the emitter affects wave intensity. Further research is needed to optimize these systems for broader uses. Balancing efficiency with safety is a challenge for engineers in this field.

Ultrasonic emitters are fascinating devices. They play a crucial role in various applications, from medical imaging to industrial cleaning. Understanding their key components helps demystify their operation. The two essential parts are transducers and drive circuits.

Transducers are the heart of ultrasonic emitters. They convert electrical energy into ultrasonic waves. Common materials used for transducers include piezoelectric crystals. These materials vibrate when an electric current passes through them. This vibration creates sound waves. However, not all transducers work efficiently. Factors like the quality of materials and design can impact performance significantly.

Drive circuits are equally important. They supply the necessary energy to the transducers. A good drive circuit ensures that the transducer operates optimally. It regulates the frequency and strength of the input. If the circuit fails, the entire system might underperform. Identifying issues in these circuits can be challenging. This complexity highlights the need for continuous improvement and innovation in design. Each component must work seamlessly for the emitter to function effectively.

Ultrasonic emitters are versatile tools widely used across various industries. In healthcare, they help in imaging and therapeutic applications. For example, ultrasonic imaging relies on sound waves to create images of internal organs. This non-invasive approach is crucial for diagnostics. Reports indicate that the growth rate of ultrasound equipment is expected to reach 8.2% annually.

In industrial settings, ultrasonic emitters serve multiple roles. They are used for cleaning delicate items, like electronic components, which require gentle handling. Furthermore, they play a vital role in non-destructive testing, assessing materials without causing damage. The ultrasonic cleaning market alone is projected to grow to $1.3 billion by 2025.

Tips: Always consider the environmental impact of ultrasonic applications. While they offer significant benefits, waste management must be part of the planning. Maintain equipment regularly to ensure efficiency. Neglecting maintenance can lead to suboptimal performance and higher operational costs. Regular checks ensure reliability, but they are often overlooked.

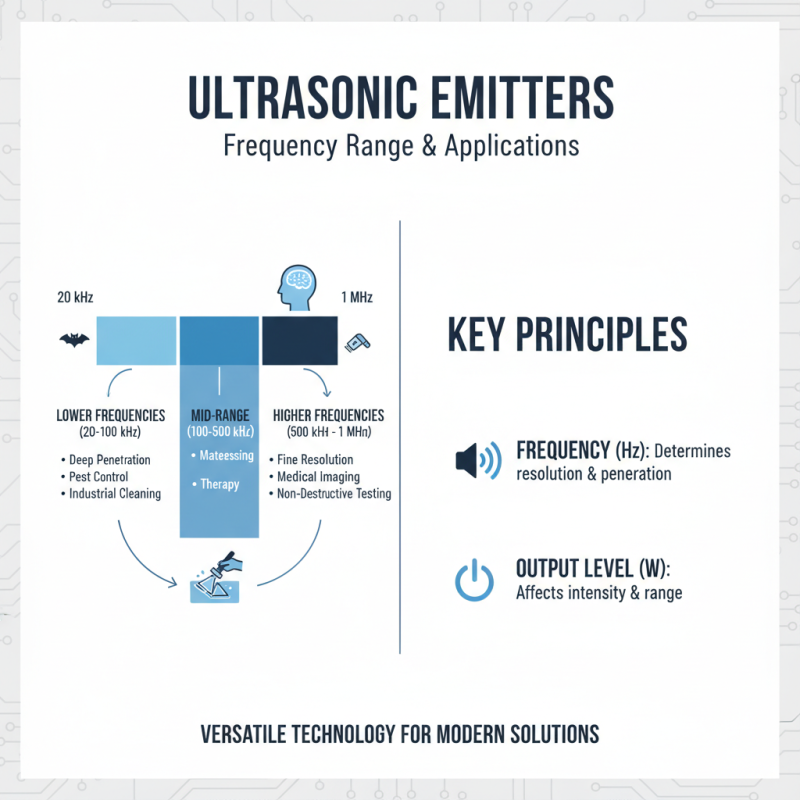

Ultrasonic emitters operate in a fascinating frequency range. They typically function between 20 kHz and 1 MHz. This range is important for various applications, such as cleaning, imaging, and pest control. The effectiveness of these devices hinges on both their frequency and output levels. Higher frequencies offer finer resolution, while lower frequencies can penetrate deeper into materials.

When considering output levels, the emitter's power is crucial. Output levels are commonly measured in decibels (dB). A higher dB means stronger sound waves. However, there is a balance to strike. Too high an output may cause interference or signal distortion. This poses a challenge for designers. They must ensure that the emitter performs reliably without unnecessary noise.

Understanding these metrics is essential. Users often overlook the importance of matching the application to the right frequency and output. A mismatch can lead to subpar results. It is critical to measure the specific needs of each situation. Evaluating the performance can lead to better efficiency. Yet, many skip this evaluation process, limiting their potential success.