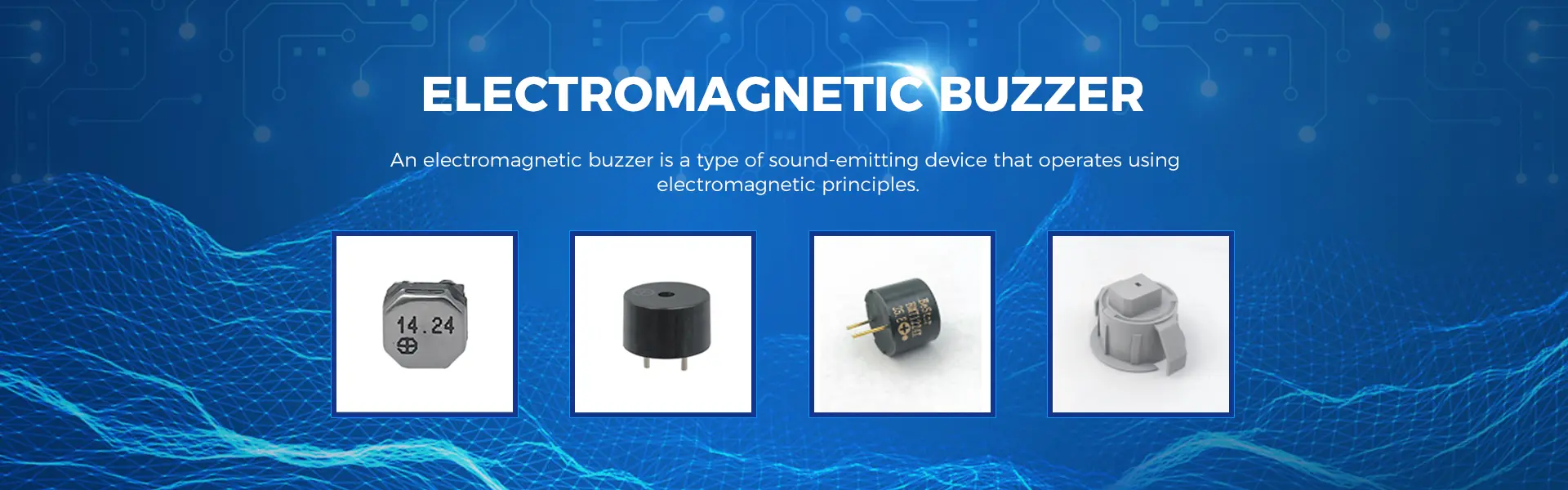

Electromagnetic Buzzer

An electromagnetic buzzer is a type of sound-emitting device that operates using electromagnetic principles. In simple terms, it generates sound when an electric current flows through a coil, creating a magnetic field that moves a diaphragm to produce a tone or alarm. Like piezo buzzers, electromagnetic buzzers are lightweight and cost-effective. They typically operate at lower frequencies and can deliver a louder, more natural sound, making them suitable for applications like alarms, timers, and notification systems. Their performance depends on design specifications such as voltage, current, and housing size.

0102030405

Show

- Prev

- 1

- ...

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- ...

- 9

- Next

- Total 9

TH2206052-C01-RO1 (42A02) LVD

TH2206052-C01-RO1 (42A02) LVD

-

Q1: What models and applications are available for your multilayer piezoelectric ceramic elements?

A1: We offer a variety of piezo ceramic elements in different sizes and frequency responses, widely used in ultrasonic detection, medical imaging, and industrial sensing. Please refer to our product catalog or contact us for assistance with product selection. -

Q2: Which international standards do BESTAR products comply with?

A2: Our products comply with RoHS, REACH, and other environmental regulations. Some models are certified by Intertek, TÜV, CE, UKCA, and SGS. -

Q3: How do I choose the right electromagnetic components?

A3: Selection depends on your specific application. Our technical team can support you with application-based design validation and recommendations. -

Q4: Do you support low-volume customization of piezo elements or inductors?

A4: Yes, we offer flexible manufacturing services from prototyping to mass production. Our low minimum order quantities (MOQs) and reliable lead times are ideal for startups and specialized projects. -

Q5: What is the typical customization process and lead time?

A5: Our typical process includes: requirement evaluation → solution confirmation → process development → sample delivery → transition to mass production. The full cycle usually takes 2–6 weeks.