From Automation to Intelligence: BESTAR SMT Division Achieves Dual Upgrades in Capacity and Quality Control

In recent years, with the deep implementation of the “Made in China 2025” strategy, the electronics manufacturing industry has entered a critical period of intelligent transformation. Under the dual drive of policy guidance and market demand, electronic intelligent manufacturing has become an important direction for industrial upgrading. Jiangsu Province, as a major hub of manufacturing, is vigorously promoting enterprises to implement intelligent transformation and digital upgrading. SMT (Surface Mount Technology), as the core process in the electronic assembly industry, is playing a key role in this transformation.

Amid this wave of intelligentization, the electronics industry in Changzhou is showing strong growth momentum. BESTAR’s SMT Division is an active participant and practitioner of this trend. The division’s 1,300-square-meter dust-free workshop is equipped with precision constant temperature and humidity systems and air purification devices, strictly adhering to the stringent requirements of SMT processes for cleanliness, temperature, and humidity, providing an ideal production environment for high-precision mounting.

BESTAR SMT Division continuously invests in advanced equipment upgrades, introducing intelligent machinery to further enhance process precision and production efficiency.

In this intelligent manufacturing space, a series of high-end equipment work in coordination: fully automated high-speed placement machines achieve precise component mounting with micron-level accuracy, with production lines capable of handling 0.3mm pitch BGA chips and 0201 miniature components, as well as high-precision FPC flexible board mounting. SPI solder paste inspection machines monitor printing quality in real time, AOI automatic optical inspection equipment performs comprehensive solder joint detection, and laser marking machines engrave unique traceability identifiers on each PCB board. At the same time, an electronic warehouse system enables intelligent material management, ensuring material traceability and accurate distribution. The seamless collaboration of these intelligent devices forms an efficient and precise modern production system.

This intelligent workshop, built in strict accordance with SMT process requirements, showcases the advanced level of modern electronics manufacturing. By adopting the “machine replaces human” model, the division has not only significantly improved production efficiency but also ensured stable and reliable product quality. The production lines fully meet the stringent quality standards of industries such as automotive, medical devices, household appliances, and smart products.

In addition, the SMT Division provides a complete electronic manufacturing service chain, including DIP insertion and wave soldering, finished product testing, aging assembly, and customized development, offering customers one-stop solutions.

BESTAR SMT Division attaches great importance to the construction of its quality management system and has successively passed IATF 16949 automotive industry quality management certification, ISO 14001 environmental management certification, and ISO 45001 occupational health and safety management certification. The establishment and implementation of these systems ensure that products are subject to strict quality control throughout the entire manufacturing process, providing reliable quality assurance for customers.

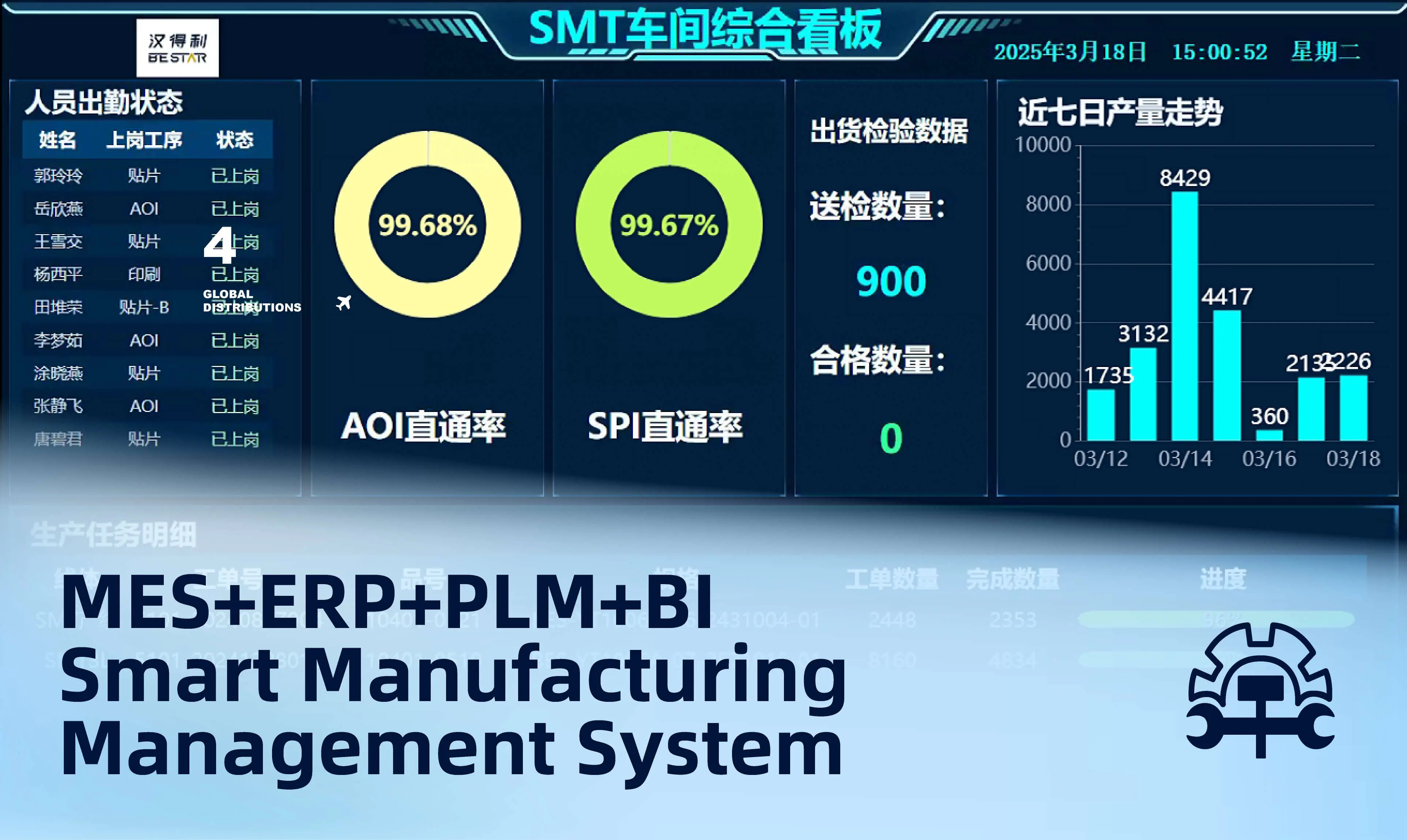

Equally, the in-depth application of intelligent management systems is another highlight of the SMT Division. The MES system realizes digital management of the entire production process and establishes a complete quality traceability system; the intelligent warehousing system enables automated material management; the ERP system integrates internal and external resources, achieving full-process digital control from order to delivery. The collaborative operation of these systems ensures efficiency, transparency, and traceability throughout the production process.

Today, products manufactured by BESTAR SMT Division are widely applied in multiple cutting-edge fields, including brushless DC motor driver boards, high-precision sensor modules, wireless communication modules, and artificial intelligence terminal devices. The business scope covers key areas such as automotive electronics, medical devices, smart home, and power tools, providing high-quality electronic manufacturing solutions to customers worldwide.

*SMT Basic Knowledge Sharing*

SMT (Surface Mount Technology), as the mainstream process in the electronic assembly industry, mounts leadless or short-leaded surface-mounted components (SMC/SMD) onto the surface of printed circuit boards (PCB) or other substrates, and connects circuits through processes such as reflow soldering.