Innovation in Millimeters: BESTAR’s Precision Manufacturing Strength

Miniaturization Challenge: The Precision Evolution of Cooling Fans

Electronic devices continue to evolve toward faster performance, larger capacity, lower energy consumption, smaller size, and lower cost. The trend of thinner laptops has imposed increasingly demanding requirements on internal cooling fans.

As devices become thinner, fan thickness must decrease as well, while delivering greater airflow within a smaller volume. This requires improving airflow by increasing the number of blades and rotational speed without significantly adding thickness or size.

However, as the number of blades increases and the thickness decreases, the manufacturing difficulty grows exponentially. Today’s ultra-thin and dense blade designs make traditional ejection methods such as ejector pins or ejector blocks difficult to balance. Any slight insufficiency in ejection force can cause the product to break inside the mold and become unrecoverable.

Breaking Through: Precision Injection Molding and Innovative Design

Faced with these challenges, BESTAR’s Precision Division demonstrates its technical strength. It is capable of producing fans with up to 103 blades and a remarkable minimum thickness of just 0.18mm.

Precision injection molding technology is the key to achieving this breakthrough. Through precise control of mold temperature, injection pressure, cooling time, and other parameters, it ensures that ultra-thin blades are perfectly formed and smoothly released from the mold.

Core Strength: Professional Team and Advanced Equipment

BESTAR’s Precision Manufacturing Division is powered by a core design team with extensive experience in developing and producing complex, high-precision injection molds. The team deeply studies production processes for 3C electronic products, providing customers with comprehensive injection molding solutions and efficient communication throughout product and mold design.

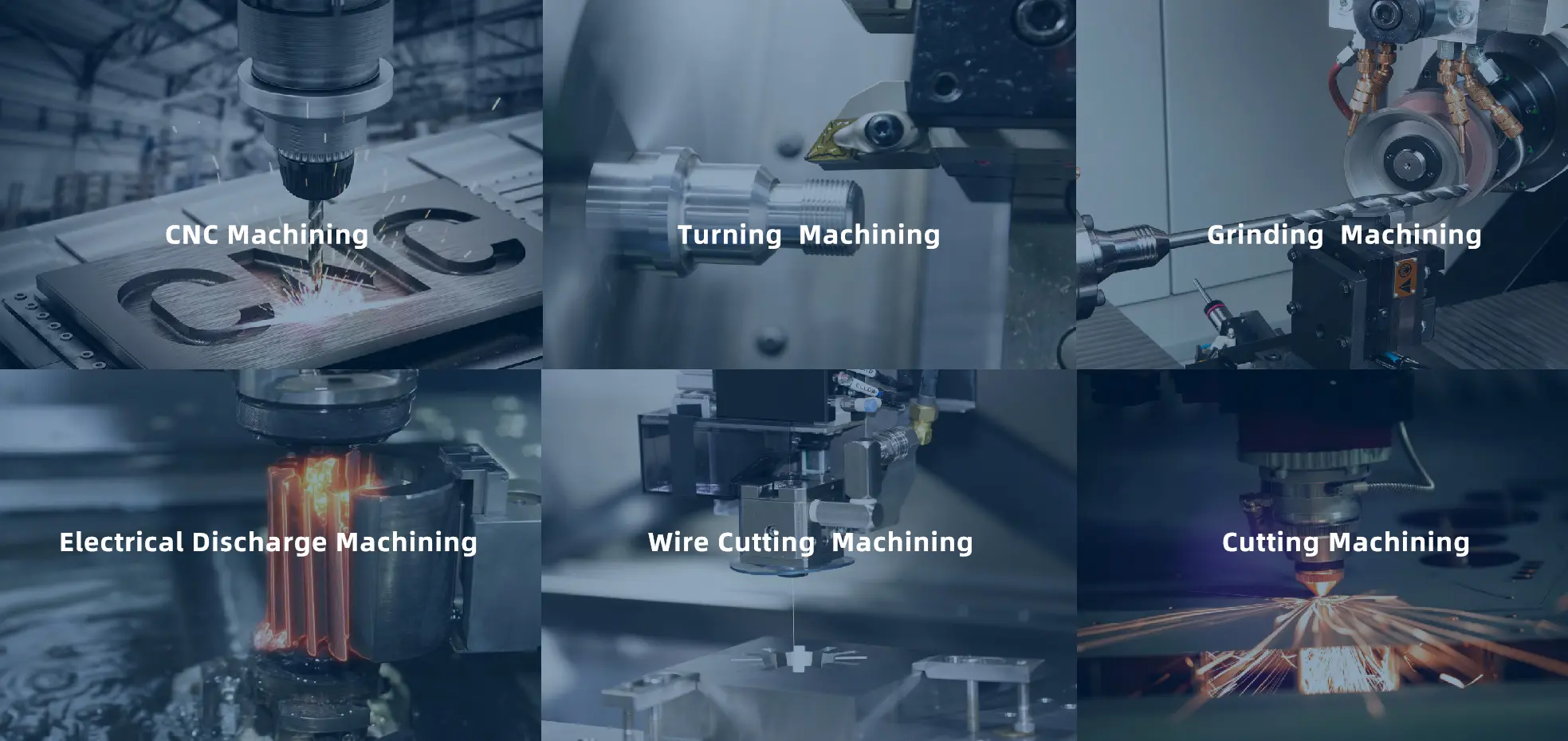

In terms of equipment, BESTAR’s precision manufacturing workshop has strong machining capabilities, utilizing six major processing methods. It is equipped with more than ten advanced machines including CNC machining centers, mirror EDM machines, and precision grinders.

Diverse Applications: From Consumer Electronics to Global Markets

The molds developed, designed, and manufactured by BESTAR’s Precision Division cover a wide range of applications, including but not limited to laptop fan assemblies, instrumentation, tools, motor frames, and monitor components. The molds are designed and manufactured to export-grade standards, reaching markets in Egypt, Russia, and across Europe.

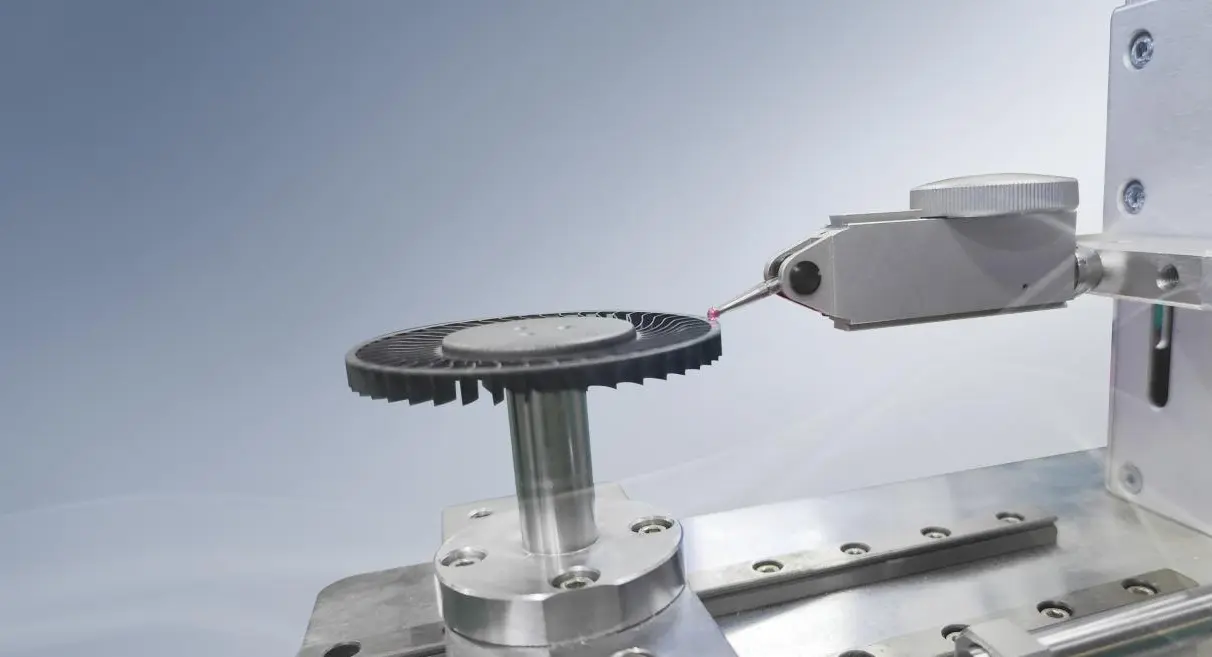

Beyond technology, every step—from R&D to final production—is strictly monitored by professional personnel. Each mold undergoes expert process adjustments and precise calibration, ensuring efficient and accurate completion of mold fabrication and debugging.

Capacity Expansion: Empowering Intelligent Manufacturing Upgrades

Since its establishment in 2012, BESTAR’s Precision Division has accumulated over ten years of experience in precision machining. Through continuous technological innovation and equipment upgrades, the division continues to push the limits in precision injection molding. Its current monthly production capacity reaches approximately 20 sets of molds and about 10 million injection-molded parts, with ample room for further expansion.

Looking ahead, as precision components extend into fields such as aerospace and intelligent equipment, BESTAR’s precision manufacturing capabilities will continue to serve as an invisible force driving innovation across industries.