Miniature Piezoelectric Fan Cooling System | Device-Level Ultra-Silent + High-Precision Cooling

Following our previous discussion on the Microfluidic Liquid Cooling System, the growing demand for smartphone performance and ongoing device miniaturization have made active cooling solutions increasingly indispensable. Today, we turn our focus to another core innovation from BESTAR—the Miniature Piezoelectric Fan Cooling System, and explore how it delivers outstanding performance in energy-efficient, targeted cooling.

As electronic devices continue to push the boundaries of miniaturization and high performance, chip thermal management has become a critical bottleneck. Traditional fan-based cooling remains effective, but noise, bulkiness, and high power consumption have become major drawbacks.

Specifically, conventional solutions face significant challenges in compact devices:

- Bulky structure (requiring motors, bearings, and magnets)

- Noticeable noise (caused by rotating blades and mechanical friction)

- Higher power consumption

- Inefficient airflow (diffused rather than directed, creating thermal dead zones and limited penetration through stagnant heat layers)

These limitations are precisely what the BESTAR Miniature Piezoelectric Fan Cooling System is designed to overcome.

Core Advantages: Ultra-Silent Operation + Precision Cooling

Compared with traditional fans, the BESTAR piezoelectric fan system offers two core advantages:

- Ultra-silent, vibration-free operation(inaudible to the human ear due to high-frequency actuation) with ultra-low power consumption.

- Extremely slim, motorless designthat generates high-speed, directional micro-jets capable of penetrating the heat boundary layer directly at the chip surface—greatly enhancing cooling efficiency.

Silent Actuation & Efficient Air Intake

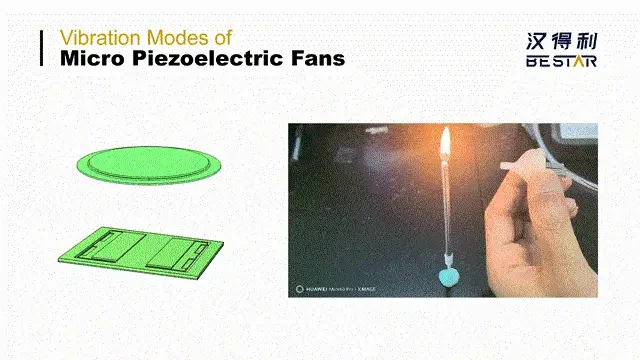

At the heart of the system lies the integration of a piezoelectric ceramic plate with metallic blades. When high-frequency AC voltage is applied, the ceramic undergoes ultra-fast deformation (≥20,000 cycles per second) via the inverse piezoelectric effect, driving the blades into vibration without any mechanical motor noise or electromagnetic interference.

This ultra-high-frequency vibration creates strong pressure fluctuations at the blade roots (up to 4.5 L/min airflow within a 300 mm² footprint). Through carefully engineered blade geometry and cavity design, the system efficiently draws in cool air from the inlet.

Energy Focusing & Precision Cooling

Once intake is complete, the vibrating blades compress and accelerate the airflow, which is then channeled through a specially designed jet plate. Micro-apertures on the jet plate focus the compressed air into high-speed directional jets, which directly strike the chip’s heat source surface.

This focused jet stream penetrates stagnant thermal layers and delivers powerful forced convection, removing heat with exceptional efficiency. Within just a few cubic centimeters, the system achieves cooling performance far beyond conventional solutions.

Engineering Excellence in Piezoelectric Cooling

Transforming these principles into a practical, high-performance cooling device requires deep expertise in piezoelectric materials, vibration mode control, and system integration. BESTAR’s extensive experience in precision piezoelectric actuation technology—from material science and high-frequency excitation to vibration-to-airflow conversion—provides the solid foundation for this breakthrough system.

Towards a Smarter, Quieter, and More Efficient Cooling Future

In summary, the BESTAR Miniature Piezoelectric Fan Cooling System demonstrates that effective thermal management does not need to come with fan noise or bulky design. Leveraging unique piezoelectric actuation and optimized structural engineering, it represents a smarter, quieter, and more compact future of chip cooling.

For applications where “silent yet powerful” cooling is essential, BESTAR’s miniature piezoelectric cooling system is rapidly becoming an indispensable tool for engineers—empowering electronic devices to achieve higher performance, smaller form factors, and superior user experiences.